METRA multi-spindle lathes

CNC Automatic Lathes Or Cnc Multi-Spindle Lathes

Managers of precision machining companies have usually this dilemma: What is more convenient for my company, standard CNC automatic lathes or CNC Multi-Spindle lathes?

Everyone thinks of competitiveness to win over competitors, as well as the best productivity and reliability for their parts. For this, investors compare tool costs, cycle times, energy savings, coolant costs, setup times, floor space, etc.

Next to this, you’ll find a comparison of the cost structure of the investment. We analyze each cost one by one compared between CNC automatic lathes and CNC multi-spindle lathes:

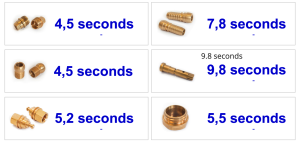

1) PRODUCTIVITY: Everyone who heard about CNC multi-spindle lathe machines knows that those are from 5 to 6 times more productive than single-spindle machines. Since in multi-spindle machines we have 6 “main” spindles, in the single spindle turret lathes we have 1 spindle and 1 sub-spindle. This means that in the most sophisticated single-spindle machines, we are only able to make 4 operations simultaneously (1 front and 1 cross operation per spindle). Since multi-spindle lathes can work under the same scheme (2 operations per spindle), the difference in productivity is obvious. In addition to these 6 spindles, we can work additionally with 1 pick-up attachment, that works as a sub-spindle. If the part has too many operations that cannot be finished 100% in the 6 (or 8) spindles, we always have this sub-spindle where we can make the remaining operations one after the other. As a result, the difference in productivity will be given by the number of operations that have to be performed: As more operations, we have to perform, more single spindles will needed to achieve the same production. If we have fewer operations, sometimes we can work on double production (2 parts per cycle).

2) TOOL-COST: Let’s remind that operations to be performed are given by the part, not by the machine. Tools are the same. The tool cost per part is exactly the same if the tools that will be used in both types of machines are the same. This happens in 99% of the situations.

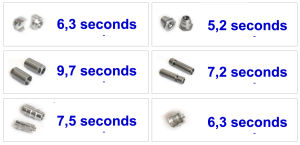

3) COST OF ENERGY and COOLANTS: It is true that CNC multi-spindle lathes have a higher UNITARY energy consumption than standard CNC automatic lathes. Just this information is not enough by itself, since the most important is the cost per machined part. As a resume, to make precise calculations, a comparison should be made between the 5 single spindles and 1 multi-spindle. If we obtain the cycle times by each machine type, then we can know for a concrete part how many automatic lathes can achieve the production of 1 multi-spindle. The result is evident: fewer machines (but the same production) = fewer costs.

4) FLOOR SPACE: For companies that don’t have too many spaces available, the multi-spindle is the right solution. This concept is sometimes related to the opportunity cost. If your finance department is considering and evaluating different investments and they calculate the productivity per sq m, numbers are unbeatable.

For more information about our CNC Multi-Spindle Lathes, contact our technicians, here.

For more information about METRA CNC multi-spindle machine production, link here.

For more pieces of information about B-L-D CNC machine distribution in China, link here

#CNCautomaticlathes, #CNCmulti-spindlelathes, #precisionmachining, #competitiveness, #productivity, #reliability, #toolcosts, #cycletimes, #energysavings, #coolantcosts, #setuptimes, #floorspace