Tech

tech category

-

INSPECTIONS SERVICES HVAC, PIPING, METAL PRODU

QUALITY CONTROL AND GOODS INSPECTIONS Our quality control “Inspections” services are divided into 3 intervention methods. A)-Passive, B-reflective, C-active. The methodologies are defined with the application of interventions, agreed with the customer but from substantially different aspects. Definitions of interventions. PASSIVE The customer provides technical data sheets relating to the products to be inspected, checks are carried out and related reports are issued. Inspections usually include part or all of the lists described here: 1- Control of production, raw material, and components 2 Control during production, on production lines 3- Pre-shipment inspection, goods packed in stock 4- Container load control, quantity, and quality of cargo 5- Monitoring of production, and collection of inspection data of supplier personnel. B)- REFLECTIVE The customer provides technical data sheets and reports of the problems encountered previously, checks are carried out on the supplier’s production line, (previous list from 1 to 5) are reflected to the customer who asks the supplier to intervene with necessary adjustments. Pictures represent delivered standard, not shining samples Definitions of interventions. C)- ACTIVE With the customer, we evaluate the elements that make up the characteristics of the product to be examined. From raw materials to certifications, technical and construction…

-

THE QUALITY OF MADE IN CHINA MECHANICAL COMPONENTS

The quality of Made in China Mechanical components is generally under-estimated. Chinese mechanical components manufacturing is the larger player in the world, but there are problems with the quality. China’s production of industrial products far exceeds its domestic consumption and exports. For example, China produced almost 50% more cars last month than Europe did combine. That means that China made about three times more automobiles last month (about 19 million vehicles) than the rest of the world put together(12.7 million units). China’s economy has grown rapidly since 2000 and the country currently accounts for 20 percent of global automobile sales. But, despite having doubled annual economic output in recent ten years, Chinese auto companies’ profitability remains low due to a dearth of advanced technology and skills. Made in China is becoming synonymous with cheapness due to the lower wages offered in comparison with developed countries. Therefore some manufacturers are looking away from labor-intensive production processes and instead focusing on design and assembly methods that require fewer workers and therefore cheaper production costs. (automation) Because of the demand for manufacturing products that are environmentally friendly and safe to consume, there is an opportunity for consumers to enjoy products produced by developing…

-

METRA multi-spindle lathes

Managers of precision machining companies have usually this dilemma: What is more convenient for my company, standard CNC automatic lathes or CNC Multi-Spindle lathes? Everyone thinks of competitiveness to win over competitors, as well as the best productivity and reliability for their parts.

-

Scouting mechanical manufacturers in China

Scouting Mechanical Manufacturers in China can be a daunting task, but with the right tools and strategies, it can be an extremely profitable endeavor. Scouting a Chinese mechanical manufacturer can be a helpful step in producing the correct product with. It is important to ask a variety of questions when scouting a factory and to consider a number of factors when selecting a company.

-

How to find suppliers in China

Finding the right supplier in China can be challenging. It’s important to identify where suppliers are located, select the right contact, and check their level of experience. Consider visiting their production centers in person to check the quality of products. If unable to go in person, consider contacting an agency to help find a suitable supplier. By following these steps and taking advantage of available resources, you can successfully find a reliable supplier that meets your needs.

-

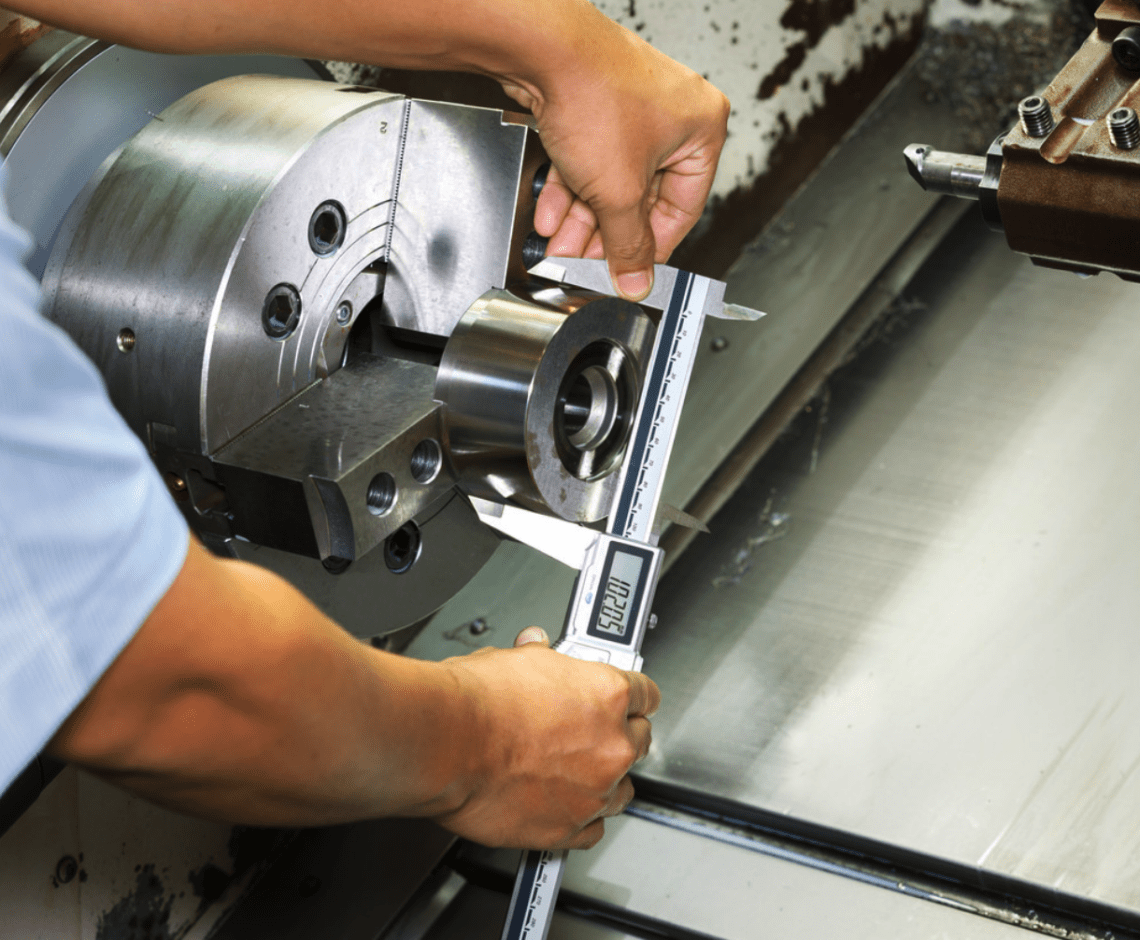

Unlocking Precision: China’s Exemplary CNC Machining Workshops for Mechanical Metal Parts

China's CNC machining workshops have transformed precision manufacturing across automotive, hydraulic, engineering, and consumer goods sectors. With expertise in producing large-sized die-cast gray iron components, precision-casting stainless steel, aluminum, and forged brass, they offer unrivaled accuracy. Cutting-edge precision lathes and multi-spindle lathe machines enable high-volume production of small components. These workshops prioritize flawless execution, adhering to customer quality plans. Their advanced technology fabricates intricate parts, meeting diverse manufacturing requirements. Setting new benchmarks, they provide cost-effective solutions for automotive and industrial applications, ensuring stringent standards for every die-cast component. Versatile operations deliver exceptional results across various materials. Through stringent quality control, they achieve rapid turnaround times in mass production. China's CNC machining workshops embody precision, reliability, and large-scale production capabilities, driving innovation and continuous improvement.